The Analytics and Prognostics Systems (APS) Laboratory

The APS lab is where many of the theoretical research developments are implemented on experimental testbeds that emulate industrial applications. This is key to ensuring that our modeling efforts can be implemented in various industrial applications and to verify the validity of model assumptions. Examples of the equipment and testing rigs utilized to support PAIS research are shown below. Click within a section to learn more about each test bed.

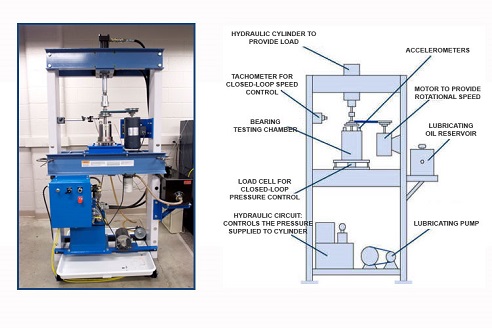

Multi-Component Diagnostics and Prognostics Research

A drivetrain diagnostics and prognostics test bed specifically designed to simulate industrial drivetrains with capability for performing accelerated degradation of gears and bearing, either simultaneously or individually (courtesy of Spectraquest).